Have I mentioned that we'll be fully self-propelled for this research? At least, on the land-based portions? As in, no helicopter support.

This is where Heidi's wonderful, awful idea comes into play. A wagon, she thought to herself, a lovely little light-weight, heavy-duty wagon to pull behind us. Surely someone else has attepted to trek across sensitive tundra in the summer with lots of gear; a cart design must already exist? But of course, that's how Heidi got the idea for this insane project in the first place; the fateful in-flight magazine. John Dunn and Sandy Briggs had rigged up the whizziest carts ever on one of their many Arctic expeditions. It couldn't be that hard, she would just google these guys, email them, and be off to the races. HOWEVER, the University of New Brunswick email server didn't see fit to forward Heidi the note from John giving instructions on sled design (she found this out two months later, BURNING FIERY PITS OF DEATH!). That's okay, Heidi should recover in about a decade.

One month, 34 trips to the hardware store, 2 trips to a welder, 1 trip to Montana, 4 trips to specialty nut & bolt stores, approximately 47 internet search hours, a final email plea to John Dunn (from Heidi's yahoo account!) and many very loud expletives later, we had: a prototype.

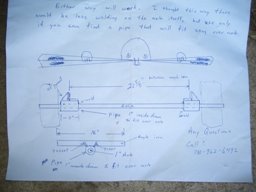

(this lovely sketch was done by Heidi's friend Ang's father; the chassis was welded by her friend Steph's brother's girlfriend's dad's acquaintance (cousin, maybe?))

Roleez (C) wheels - lightweight, low-impact wonders! And boy, is

aluminium light...

aluminium light...We tried a few different attachment systems - the first idea, courtesy of Ed Bouffard, was to have flexible joint at the sled end, a stong yet flexible pole, and then hook into the waist band of a pack. You'll note that the system on the left in this photo involves duct tape: we ultimately decided that it is unwise to have duct tape as part of the primary design...

At the end of the day, we have two designs: one, a modification of ski pulk pole design by Ed in Minnesota, with rotating ball joints at the sled end and strong flexible fibreglass poles (I won't even bother mentioning how hard it was to find a machine shop in Edmonton that would thread fibreglass; and does anyone know where to find 5/16-13 to 1/4-20 reducing couplers???); the second system, courtesy of John Dunn, has aluminum poles, webbing, pvc pipe, and a few bolts...

No comments:

Post a Comment